Formed silicone seals

Formed silicone seals are an important component in many industries, ranging from automotive to aerospace to medical devices. These seals are made from silicone material that is formed into specific shapes to fit various applications. One of the key advantages of formed silicone seals is their ability to withstand extreme temperatures and resist chemical and environmental degradation.

The manufacturing process for formed silicone seals typically involves molding the silicone material into the desired shape. This can be done using a variety of techniques, including compression molding, transfer molding, or injection molding. Each method has its own advantages and is chosen based on the specific requirements of the seal.

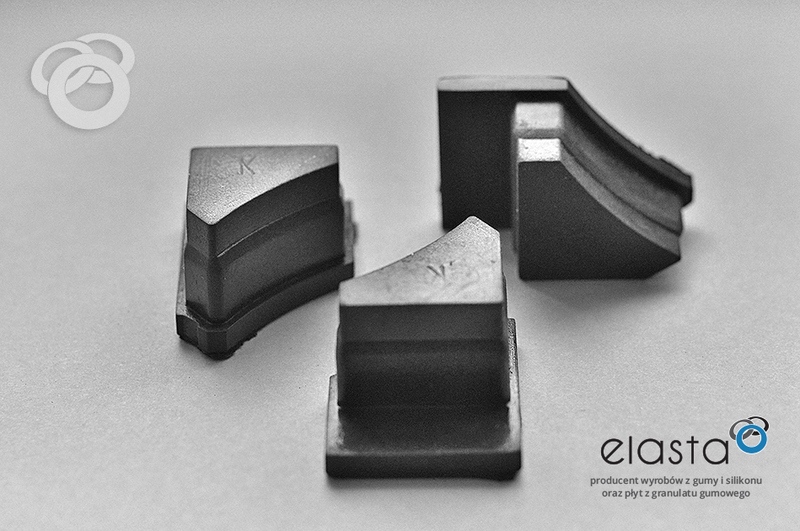

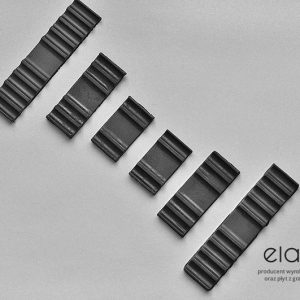

Formed silicone seals can be customized to fit a wide range of applications, from simple gaskets to complex sealing systems. They can be designed to fit specific geometries, such as curves, angles, and irregular shapes, making them ideal for sealing joints and connections in machinery and equipment.